The types of cutting tools are defined mainly on the type of material to be machined. You also have to consider the type of cut to be done, the number of products to be created, and the quality of each item.

Here is the classification of the types of cutting tools that are used in machining.

Types of Cutting Tools That You May Choose From

Metal cutting technology involves the use of cutting tools for different machining operations.

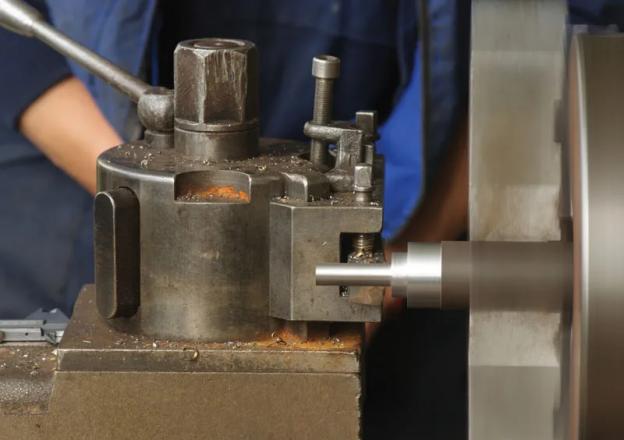

Single Point Turning Tool

The single-point turning tool is a type of cutting tool that is used on lathe machines. These machines are mainly designed to shape metals and even wood. In this machining equipment, the rotating part is the workpiece while the stationary part is the cutting tool.

When using the single-point turning tool, remember to align all angles of the lathe machine so that the cut will be done accurately. You also have to understand the orientation of the machine. The headstock should be on the left while the tailstock is on the right.

Drills

A drill is another cutting tool that pierces a hole in the metal. Drills have a cutting section and a groove so that the chips will automatically be removed. You may have seen drills before inside the house where parents perform DIYs. The same concept is true for drills and the machining industry. Particularly, the drills are the tools to use when creating a hole in machined metals.

Milling Cutter

Compared to the drill, the milling cutter has edges that act as a cutting tool. It is composed of a disk with blades on the exterior section. The milling cutter does its job as the workpiece rotates.

For rolling mills that reduce the size of a cylindrical body, solid CBN inserts are utilized. CBN means cubic boron nitride inserts. CBNs are characterized as having high heat resistance as well as high hardness.

If you do not have CBN inserts, you may want to contact solid cbn inserts manufacturers so that you will have a steady supply of inserts for your projects.

Broach

The next type of cutting tool is through the process of broaching. It can be rotary or linear. This tool uses a toothed tool called a broach to cut through the metal. Broaching can be done on the surface or inside the workpiece. You can do modular, Keyway, concentricity, and cut-recut.

Thread Cutting Die

If you want to cut inside of the hole, you may want to pick up a thread cutting die. The thread cutting die cuts the male thread while the workpiece is Turning.

Reamer

Another commonly used cutting tool is the reamer. To use the reamer, first, you have to clean the device for any chips that were left by the previous user. You then use parallels in the vise and secure properly.

The reamer is used to finish the hole created by the drill. Make sure to use a reamer that is smaller than the drill. You should also slow down the rpm of the reamer and avoid the pecking motion of the reamer.

End Milling

End Milling utilizes tools that have teeth at the sides and end of the mill. Some of its applications include tracer milling, profile milling, face milling, and shape milling.

Conclusion

You have to keep in mind the type of cutting tool to use for your project. Not considering this can cause accidents. It can also ruin your metal as well as damage the machine itself. If you are a beginner at machining, you should seek the help of a professional if you want to experiment. And be sure to wear protective clothing and goggles when using these cutting tools.