Compaction is a process of improving or increasing the density of soil by a manual or mechanical method. It is employed to make the soil more stable and increase the bearing capacity of the soil layer on the construction site.

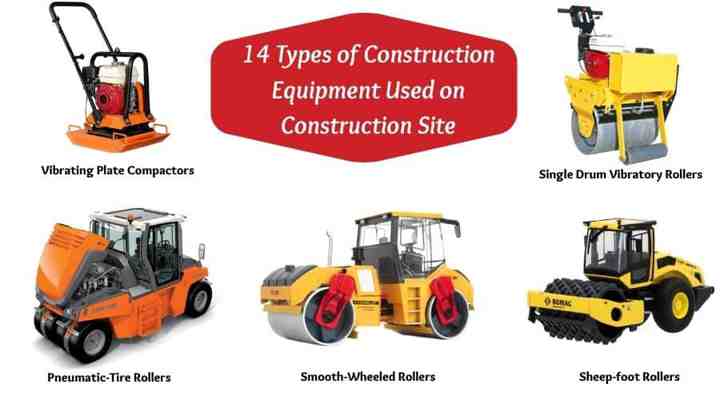

There are different types of compaction equipements used on construction sites such as Smooth-Wheeled Rollers, Multi-tyre, Pneumatic-Tire Rollers, Heavy Pneumatic-Tyre Rollers, Sheep-foot Rollers, Tamping-foot Rollers Grid Rollers, etc.

Compaction equipment is often got by using a vibrating or non-vibrating steel drum roller, a pneumatic-tire roller, a grid or cleated roller, or a sheep-foot roller. Each is top suited to specific applications.

A large steel drum vibratory roller is often considered the best for general use. The range of materials that can normally be compacted economically with each type of roller is shown below. Compaction in cohesive soils is best accomplished by impact and weight to raise the soil density. The impact is required to break down the cohesive bond to enable the soil to become denser.

Compactions in granular soils are best accomplished by vibration. The options are static compactors that simply apply weight and tend to compact from the base of the layer up, vibratory compactors that use a mechanical action to consolidate soil particles, and impact compactors that use a high-amplitude hit to compact material. A pneumatic-tyre roller may be used to cover off earthworks from rainwater.

The details of all the compacting machines which are available for subgrades and pavements, and the situations for which they are best suited, is described as below.

Types of Compaction Equipment used on Construction Site

Various Types of Compactors as follows,

It is used for the compaction of crushed rock, sands, gravels, and other granular materials. In general, they’re not suited to silts or clays but they can be used for compaction of these materials.

The performance of smooth-wheeled rollers compaction equipment depends on the mass of the roller, width, and diameter of the rolls. Safety issues need to be considered when using these rollers on wet roads with cross-fall.

This type of roller compaction equipment is usually self-propelled, with smooth tires on two axles in an offset arrangement, so that the wheels on one axle tracks are within the gaps between the wheels on the other axle.

The mass of the roller is often increased by attaching ballast, and therefore tire pressure is usually variable. Very thin soils with little or no cohesion, for example, silt, sandy silt, and clayey soil, compact well when using these rollers.

These rollers have four equally spaced independently suspended tyres and should be ballast loaded up to an entire mass of fifty tonnes. They’re usually towed and are suitable for similar soils to the multi-tyre pneumatic-tire rollers, also as for gravels and finer silts.

The difference between these and multi-tyre pneumatic-tyre rollers is that the heavy pneumatic-tyre rollers can compact deeper layers, and therefore the surface density achieved is bigger.

This type of rollers is used for compacting fine-grained soils such as silty clays and heavy clays. They are generally used for the compaction of soils in dams, embankments, pavements, and railroad construction projects.

Sheepsfoot rollers compaction equipment also have two types like static and vibratory. Vibratory types rollers are for compaction of fine-grained soils and also soil with sand-gravel mixes. Generally, this type of roller is used for the compaction of subgrade layers of road and rail projects.

It consists of steel drums, on which the projecting lungs are fixed and may apply 14 kg / sq. Cm. Or so much pressure. A variety of leg types are broad bases of a spindle shape, prismatic, and clubfoot types.

Sheepsfoot rollers compaction equipment efficiency can be achieved when the lugs are doing gradual walkout of roller lugs with regular coverage. Efficiency is influenced by the pressure on the foot and the coverage of the ground obtained per pass.

For the required pressure and coverage of the ground, parameters such as the gross weight of the roller, the area of each leg, the number of lugs in contact with the ground at any given time, and the total number of feet per drum are considered. The compaction of the soil is mainly due to penetrating feet and pressure on the soil. The pressure is maximum when one leg is perpendicular.

Coverage of ground affected by pressure on the foot and received per pass. For the required pressure and coverage of the ground, parameters such as the gross weight of the roller, the area of each leg, the number of lugs in contact with the ground at any given time, and the total number of feet per drum are considered. The compaction of the soil is mainly due to penetrating feet and pressure on the soil. The pressure is maximum when one leg is perpendicular.

These are similar to sheep-foot rollers, although the legs are wider, shorter, and closer than the sheep’s feet. They are also often diamond-shaped.

These types of compaction equipment can be self-propelled or towed and will compress a wider range of soils than sheep-leg rollers, including silt and rock fragments, but not uniform sand.

Read More: What Is Surveying? 23 Different Types of Surveying Equipment

The rolls on the grid rollers are usually made of a mesh of 20 mm diameter bars spaced 100 to 150 mm in both directions. Alternatively, they may be smooth drums with a pattern of square holes shaped into the surface.

They are mainly useful for scoria-type fills (random mixtures of large and small particles, usually angular and fairly soft). Their special use is in breaking oversized stones and forcing them under compact surfaces.

These rollers have a rotational unconventional weight to produce a vertical acceleration for the compaction of the material. They have different types of drums, such as smooth wheel and sheep-leg. The force applied to the soil is proportional to the acceleration in the vertical direction, so they have better performance than stationary rollers.

Vibrating rollers type compaction equipment is suitable for compacting non-adhesive clay, compacting from the base towards the surface, always leaving a layer of loose material on the surface.

This is due to the bouncing effect between the particles of that layer as the vibration effect is shifted downward. This can be easily overcome by using medium to low weight and low amplitude compactors or by turning off vibrations.

The primary characteristics of vibratory compactors are the weight of the vibration component (drum or plate), applied to the ground through the component, and the frequency and general amplitude of the vibration.

A low layer thickness can be compacted, with low weight, low amplitude, and typically high frequencies. The frequency is usually not significant, except that the higher it is, the less the pass required, and the faster the compactor can travel to achieve optimal condensation per pass.

When using vibratory compactors, a pattern must be followed, to avoid gaps in pass coverage. It is also important not to overstuff the material. When the drum bounces on a hard surface, a distinctive ‘ringing’ noise can be heard.

This can cause damage to the roller, and will also reduce the density of the material. Therefore, for very thin layers (30 mm), especially granular or sandy materials, two passes may be sufficient, and four passes may be too high.

Granular materials up to 250 mm can be successfully deposited with these rollers in four to 10 passes, provided that they are properly calibrated to obtain the most appropriate weight, frequency, and dimensions.

To complete condensation, it is usually necessary to operate the roller without vibration for two to four passes to strengthen the surface.

These are typical of a large single vibratory drum type with large rubber equipment. They are generally used for difficult terrain and thick layers of earth.

Some rollers of this type are equipped with rubber-coated drums, which have been shown to be effective for the compaction of chips in chip seal manufacturing.

Read More: 75+ Construction Tools Name and Their Uses with Image

Static rollers compact material driven by pressure only. The thickness of a loose layer of material of 100 to 150 mm is compacted at any time, and a large number of passes are required to achieve full-depth condensation.

These rollers are compact from top to bottom. Only the first 50 mm of material is usually narrower than the first four or five passes, and further 20 or 30 passes may be necessary to complete condensation. A major disadvantage in the use of these rollers is the crushing effect on the upper compressed material, which can produce highly fine materials, affecting the quality of the base course.

A variety of rollers are available, including tandem and three steel wheels of 8 to 12-ton rollers, sheep-toes, and grid rollers used for bulk material compaction.

Track rolling will produce an attractive surface finish, but it has a negligible condensation effect. Commonly used by forest road contractors for compact road and landing surfaces. However, tracks for construction equipment are designed for low ground pressure.

By definition, this means that tracked equipment is bad for condensation. Time and money spent tracking rolling will be invested in better-dedicated equipment. However, track rolling is probably better than nothing and can reduce surface scrape.

These small compactors, usually hand-operated, have relatively low output in terms of compact soil / hour volume. Typically, these compactors are used for compacting materials, which are used in excavation in confined spaces, such as in trenches and around culverts.

Condensation of the material must be completed in layers using a power rammer. For granular soils, the layers should not be more than 230 mm thick, while for clinging soils, the layers should not be more than 1 mm thick. Power rumors have a vertical movement from 12 mm to 150 mm at a frequency of 20 to 200 blows per minute.

These compacts are available in weights reaching from 50 to 150 kg and have an operating frequency of 400 to 10,000 vibrations per minute with reduced amplitude. Vibration plate compactors are used to compressed layers of 75 mm – 10 mm mm, the thickness of materials, and are ideal for small areas (up to 20 m), with 4–4 pass for finest compaction Is required.

These compactors are hand-operated, and are ideal for granular materials with compact layer depths of up to 120 mm with four to six passes. They operate in high frequency, low amplitude mode.

You May Also Like:

• 75+ Construction Tools Name and Their Uses with Image

• 25 + Types of Doors for Your Perfect House